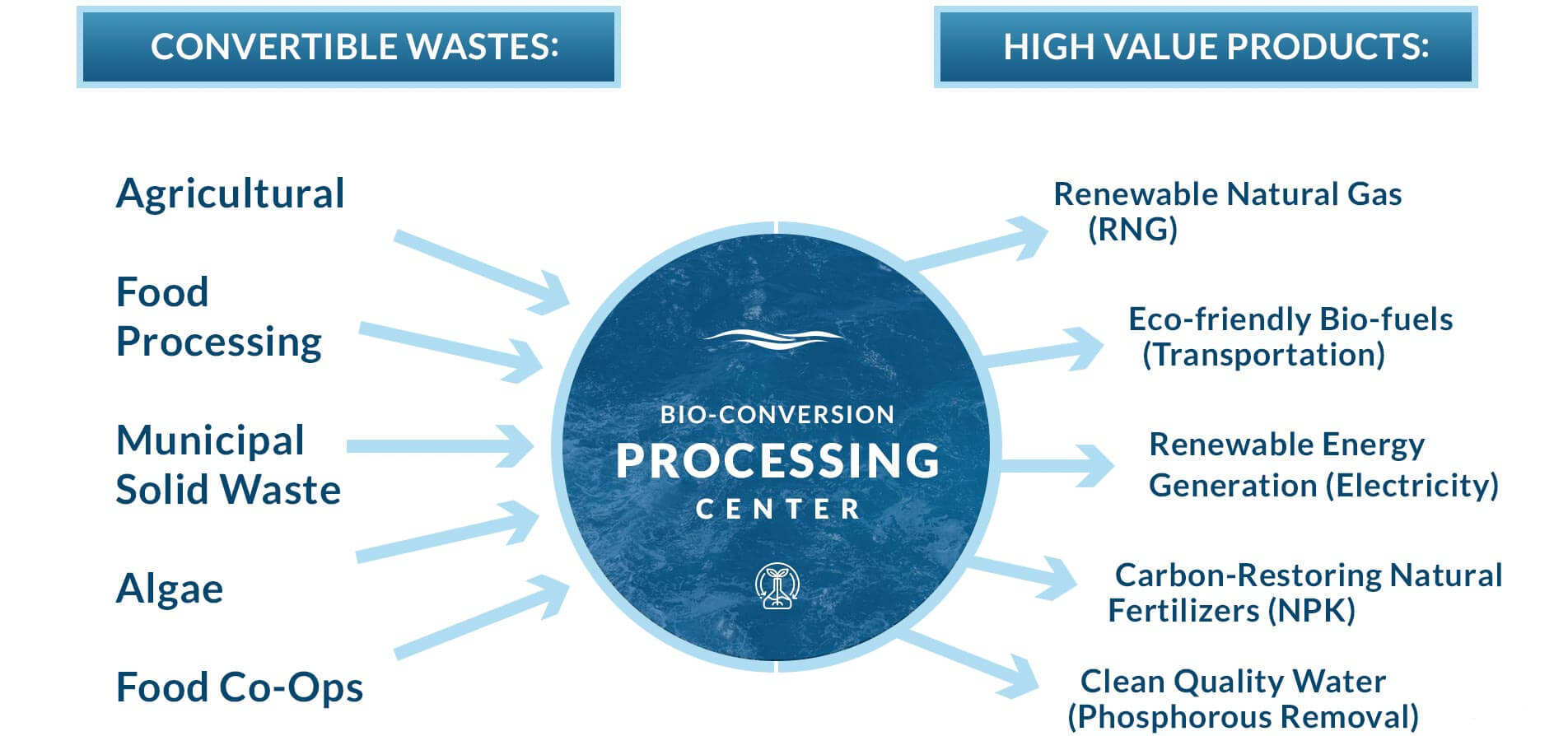

Food, Energy and Water are the essentials of life. Producing them sustainably, on an increasingly crowded planet, is a generational challenge we

ALL must face. We have accepted that challenge!

Our Planet Saver technologies help leading industries achieve sustainability at scale.

Together, creating a brighter FEWture for ALL.